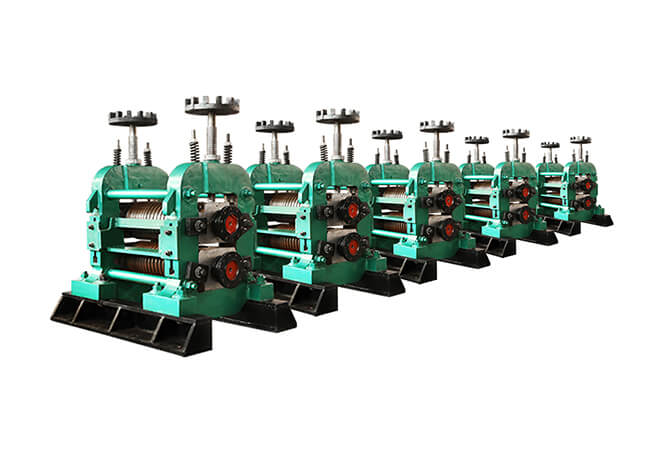

The main equipment of the rolling mill includes working stand, connecting bearing, gear stand, main coupling, reducer and so on.

On the rolling line, the working conditions are poor. Because the equipment is exposed to high temperature, humidity and dust for a long time, it is easy to be corroded. Therefore, there are high requirements for the lubrication of equipment.

Today, the editor of Judian will introduce you some knowledge about rolling mill lubrication.

In the steel rolling process, a process lubricating cooling medium must be added between the contact surface of the roll and the rolling material.

These lubricating media can reduce the friction between the roll and the rolling material and reduce the power consumption of the equipment. After the lubricating medium is used, the temperature can be controlled, the steel becomes easy to stretch, and finally the quality of the rolled product can be improved.

There are many structures of rolling mills, and each one has different requirements for lubrication. For example, the structure of sliding bearings and rolling bearings is relatively simple, and can be lubricated by monomer dispersion.

Common rolling mill lubrication systems include dynamic pressure system, static pressure system and dynamic and static pressure mixed system. We usually have the following requirements for lubricating cooling medium

Extreme pressure

Machine bearings are subject to large rolling forces and impact loads. Poor rolling lubrication will directly cause bearing scratches or even burn accidents.

seal

For dry oil lubrication, most of the grease plays a sealing role, except for a small part of the lubricating role.

water resistant

The bearing seat of the hot and cold rolling mill will be affected by cooling water or other media, such as the intrusion of emulsion, which will cause the working surface of the bearing to corrode, which is quite harmful to the bearing and is also the main cause of bearing wear.

heat resistant

The hot rolling temperature of steel is generally 800~1250℃, and the temperature of the roll surface in the deformation zone can be as high as 450~550℃, so a large amount of water needs to be used to cool the roll.

shear stabilization

The rolling speed of hot rolling and cold rolling equipment is very high. The roll bearing grease is required to have good shear stability.

This is the knowledge about rolling mill lubrication, I hope to help you. Welcome to Luoyang Judian, you can consult us about anything about rolling steel production.

Please send us your request and we reply to you with in 24 hours.

Submit Request