A section rolling mill is a type of rolling mill that is used to produce various sections or shapes of metal, such as I-beams, channels, angles, flats, and rounds. Section rolling mills are designed to process metal stock, such as billets or slabs, into finished sections by passing them through a series of rolling stands.

Section rolling mills are typically used in steel production facilities and other metalworking plants that require the production of structural shapes with specific dimensions and properties. The rolling process involves reducing the thickness and changing the shape of the metal stock by applying a series of compressive forces as it passes through the rolling mill.

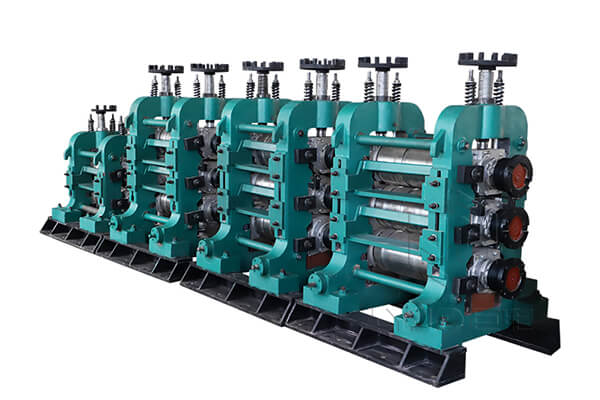

The section steel production line is typically composed of a series of rolling stands, which are arranged in a line and connected by a conveyor system. Each stand contains a pair of rolls that are used to deform the metal stock as it passes through the stand. The rolls are typically made of hardened steel and can be shaped to produce specific section shapes and sizes.

In addition to the rolling stands, section rolling mills may also include other equipment, such as cooling beds, shears, and straightening machines. Cooling beds are used to cool the finished sections after they are rolled, while shears are used to cut the sections to the desired length. Straightening machines are used to straighten the sections and remove any residual curvature that may have been introduced during the rolling process.

There are several advantages of using a section rolling mill in the production of metal sections. Some of the key advantages include:

Versatility

They are capable of producing a wide range of shapes and sizes, including I-beams, channels, angles, flats, and rounds. This makes them highly versatile and suitable for use in many different applications, from construction to manufacturing.

Precision

Section rolling mills are designed to produce sections with precise dimensions and properties. This allows manufacturers to produce sections that meet specific design requirements and perform reliably in use.

Efficiency

Section rolling mills are highly efficient and can produce large volumes of sections quickly and cost-effectively. This is particularly important in high-volume production environments, where time and cost savings are critical.

Consistency

Section rolling mills are designed to produce sections with consistent properties and dimensions. This helps to ensure that the sections perform reliably in use and meet the required quality standards.

Customization

They can be customized to produce sections with specific properties, such as strength, durability, and corrosion resistance. This makes them highly suitable for use in specialized applications where specific properties are required.

Section rolling mills are an important part of the metalworking industry, and their ability to produce high-quality sections with precise dimensions and properties is essential for many manufacturing applications.

Please send us your request and we reply to you with in 24 hours.

Submit Request