Continuous casting and rolling production line for wire rod and section bar is an advanced method to produce various kinds of wire rods and section bars. It consists of induction furnace, continuous casting machine (CCM), heating furnace, rough rolling machine, continuous rolling machine, flying shear, cooling bed, cutting to length shear, and package table. Today, we will introduce the details of every part of the production line to you.

It is use to melting steel, copper, aluminum, and other metals, and widely applied to the steel plants and casting plants. It is of fast melting speed, high efficiency, and strong adaptability. What’s more important, it can work more than 24 hours continuously.

Usually, the furnace body is made of aluminum alloy if the capacity is less than 5 tons, while steel shell for more than 1 ton capacity.

Also, the induction furnace has a simple structure and is easy to maintain. You can ask our technicians for help or fix it by yourself.

The continuous casting machine is an equipment to solidify the liquid steel to steel billet. If you want to know more about the CCM, please refer to our product page of Continuous Casting Machine.

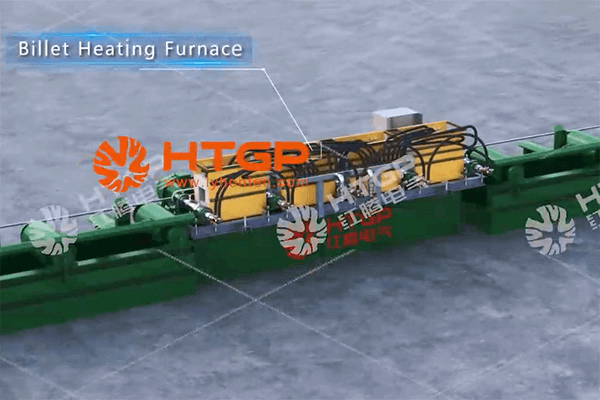

The heating furnace is to heat the billets pulled out of the CCM. We can choose different frequency to get the best heating effect according the different sizes of billets. The most outstanding feature for the heating furnace is no need to warm up before using.

Rough rolling machine, also called billets rolling machine or billets rolling mill, is mainly used for reciprocally rolling the steel billet heated by the heating furnace, and forming it into a certain size of the intermediate billet for the continuous rolling mill.

The diameter of the rollers is between 200mm to 650mm and the rollers can work effectively until they roll about 3,000 ~ 4,000 tons of steel billets.

The continuous rolling machine is an advanced process that reduces the work load and improves the rolling speed. When the billet comes to the continuous rolling machine, it will be rolled by several rolling machines simultaneously in the same direction. This simplifies the process, reduce the transport equipment, and save the initial investment and production cost. What’s more, the continuous rolling machine can shorten the producing time to ensure the deliver time.

It is a common tool that is widely applied to cut the continuous steel billet to a set length, thus the main production line will not be interrupted and it can improve the efficiency.

Luoyang Judian is a professional manufacturer of continuous casting and rolling production line for wire rod and section bar. Setting up at 2011, we have more than 10 year industrial experience and a professional technique team to provide considerable service for our customers all over the world. If you have any questions about the production line or other equipment, please to contact us right now.

Please send us your request and we reply to you with in 24 hours.

Submit Request