With the construction more and more needed, the demand of rebar and other steel products are larger and larger. That requires a high efficiency of the steel plant. The continuous casting machine has become to be the prerequisite equipment to improve the production efficiency, reduce the cost, to occupy the market for most steel plants.

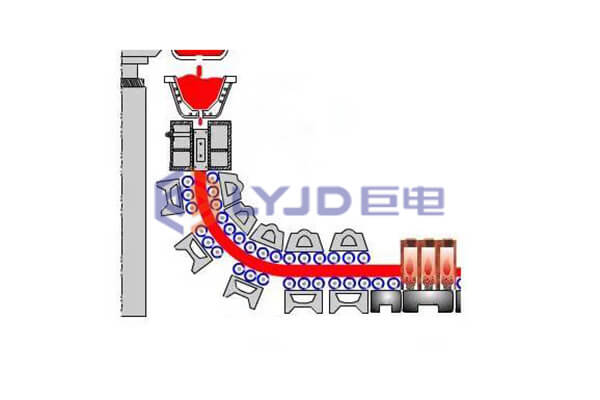

Continuous Casting Machine, also called CCM or CC, consists of ladle, ladle turntable, tundish, mold, water cooling system, mold vibration device, tension leveler, dummy storage device, shearing device, billet transporting device, etc. CCM is advanced equipment that produces steel billet, round steel, and other metal billets. It realizes that the same billet can be rolled by different mills towards the same direction simultaneously.

Continuous Casting is a manufacturing process in which metal is melted into liquid, and then the liquid metal is poured into a set of condensing equipment. In the case of partial condensation of the metal, a casting of a certain length and shape is pulled from the other end of the condensing equipment. The equipment used for this manufacturing process is called continuous casting machine or continuous casting equipment.

First, the scrap metal or mined iron ore (need more investments) will be put into a furnace for sintering and melting into liquid molten steel, followed by quenching and tempering to remove nitrogen, sulfur, and phosphorus to form molten steel that meets the requirements of continuous casting. On the turntable, the ladle is placed at the pouring position above the tundish by rotating the turntable;

Then, open the sliding door switch at the bottom of the ladle, inject molten steel into the tundish, adjust the stopper rod to control the flow rate of molten steel to enter the mold according to the production requirements, and in the mould, the molten steel is cooled inside to make the liquid flow crust to form castings. After the crystallizer vibration and the secondary cooling device, the molten steel gradually forms the casting billets from the outside to the inside;

Third, the casting billet is pulled out by the pulling device and straightened by the secondary cooling to form a solidified billet;

Finally, the casting billet is cut by a cutting device to form a casting of a specific length, which is processed in batches through a conveying device or directly enters the continuous rolling mills.

In the 1980s and 1990s, continuous casting technology was adopted by countries all over the world as a mature metallurgical casting technology, and various steel manufacturers also generally established a complete training and production maintenance system.

As one of the most professional continuous casting machine manufacturer, Luoyang Judian can not only provide high-quality equipment, but also has an experienced installation and maintenance team that can provide considerable customer service, such as quick-response, detailed equipment maintenance, technical support, customized solution, and so on. Basing on them, Judian has won a great reputation between our customers home and abroad. And, that’s why a lot of steel plants choose to cooperate with Judian. So if you have any questions about the continuous casting machine or the whole rebar production line, please do not hesitate to contact us to get help.

Please send us your request and we reply to you with in 24 hours.

Submit Request