To install a section bar production line, you will typically need a range of equipment and machinery. The specific requirements may vary depending on the scale and complexity of the production line, as well as the type and size of section bars you intend to manufacture. However, here are some essential equipment commonly used in section bar production lines.

This equipment is responsible for the efficient handling and storage of raw materials. It includes equipment for storing, handling and transporting raw materials such as steel billets or slabs. It may involve overhead cranes, forklifts, conveyors, and storage racks.

Overhead cranes are commonly used for lifting and moving heavy steel billets or slabs. Forklifts are used for smaller loads and maneuvering within the production facility. Conveyors are used to transport the raw materials between different stages of the production process. Storage racks or bins are used to organize and store the raw materials.

If you are starting with solid raw materials like steel billets, you will need heating and melting equipment to transform them into molten metal. Electric arc furnaces (EAF) and induction furnaces are commonly used. EAFs use electric arcs to melt the metal, while induction furnaces use electromagnetic induction to generate heat. These furnaces are designed to handle the specific requirements of the metal being melted.

Once the metal is melted, a continuous casting machine is used to shape it into continuous billets or slabs. The molten metal is poured into a tundish, which is a reservoir that feeds the metal into a water-cooled mold. The mold is typically made of copper or steel and has the desired shape and dimensions of the section bar. As the metal solidifies, it is continuously pulled through the mold by rollers. Cooling systems, such as water sprays or air jets, help solidify the metal.

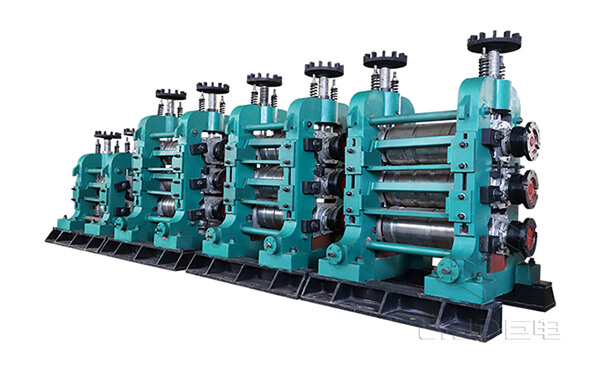

The rolling mill is a crucial component of the production line where the continuous cast billets or slabs are rolled and shaped into section bars. The rolling mill consists of a series of rolling stands, each containing two or more rollers. The billets or slabs pass through these stands to gradually reduce their cross-section and achieve the desired shape and dimensions. The rollers exert pressure on the metal, causing it to deform plastically and elongate. The rolling mill may include guides and cooling systems to control the process and ensure the quality of the section bars.

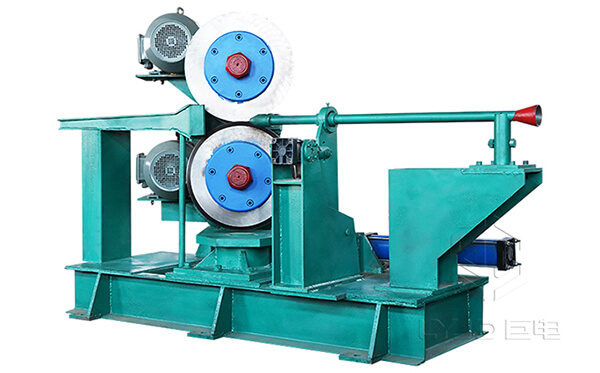

Once the section bars are rolled to the required length, cutting equipment is used to separate them from the continuous stream. Flying saws are commonly used for high-speed cutting, where the bars are cut while they are in motion. Stationary shears can also be employed for cutting the bars when they are fixed. The cutting equipment ensures that the section bars are cut accurately to the desired lengths.

Section bars may sometimes have distortions or bends caused by the rolling process. Straightening machines are used to correct these deformations and ensure the bars are straight. Finishing equipment like chamfering machines can be used to shape the ends of the bars or create specific edge profiles. Surface treatment systems may also be employed to improve surface quality, such as descaling or applying protective coatings.

Quality control is essential to ensure that the section bars meet the required standards. Non-destructive testing equipment, such as ultrasonic or magnetic particle testing, can be used to detect any internal or surface defects in the bars. Dimensional inspection tools are employed to verify the accuracy of the dimensions and geometrical tolerances. Other testing equipment, such as hardness testers or spectrometers, may be used to assess the mechanical properties and chemical composition of the section bars.

Once the section bars are ready, packaging equipment is used to bundle and protect them for transportation. Bundling machines apply straps or bands to secure multiple bars together. Strapping tools are used to tighten and seal the straps. Labeling systems can be employed to add identification tags or labels to the bundles. Material handling equipment like cranes, forklifts, or conveyors are used to move the finished section bars within the production facility and load them onto transport vehicles.

These equipment types form the core components of a section bar production line. However, it's important to note that the specific equipment and machinery used can vary depending on the production requirements, the type of section bars being manufactured, and the technological advancements in the industry. It's advisable to consult with experienced professionals or equipment suppliers who can provide more detailed information and guidance tailored to your specific needs.

Luoyang Judian is a professional manufacturer of section bar production lines and welcome to consult should you have any problems with the section bar production lines.

Please send us your request and we reply to you with in 24 hours.

Submit Request