In the current steel plants, there are many types of rolling mills. Different rolling mills require different plant areas. Today, we will take the continuous rolling mill as an example to introduce to you how much workshop area a small scale steel rolling production line needs.

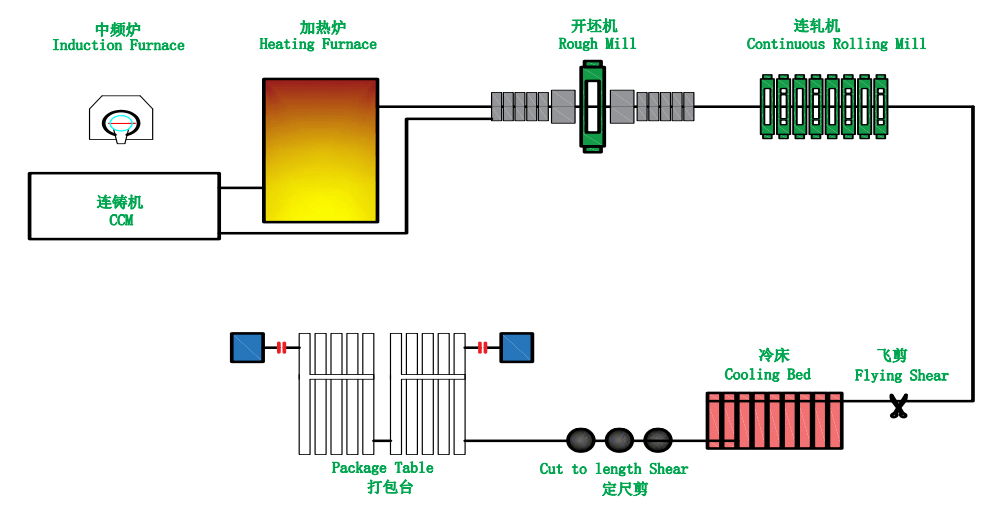

First of all, we need to know what equipment is generally in the small scale steel rolling production line. In general, the necessary equipment in a small scale steel rolling production line mainly includes a continuous casting machine, a heating furnace, a roughing rolling machine, several continuous rolling mills, a flying shears and a cooling bed. The size of these devices varies greatly, and reasonable planning is required to save the area of the plant to the greatest extent.

Continuous casting machine is a device that continuously casts high-temperature molten steel into billets with a certain cross-sectional shape and a certain size. There are two types, all-in CCM and vertical casting mahcine. Here we take the all-in CCM as an example. The size of the continuous casting machine with different output is not the same, and the occupied area will naturally be quite different. Take the continuous casting machine with a radius of 3.5m as an example: the radius of the whole continuous casting machine is 3.5m, the height of the casting machine is 3.6m, the length is 5m-6m, and the width is 1.3m. If the workbench is added, the whole machine covers an area of about 15m2.

The determination of the continuous casting machine model can be determined according to the variety, specification and height of the plant.

In most steel plants, the length of billets produced will not exceed 2 meters. After the billet comes out of the continuous casting machine, it will enter a roller table, and then enter the heating furnace through the roller table. This roller table is slightly longer than the length of the billet, about 3m.

under normal circumstances, the floor area of the heating furnace is about 15-30m2. The production operation of the heating furnace is simple, the material in and out is flexible, and the degree of automation is high. It can be opened as it is used without preheating in advance.

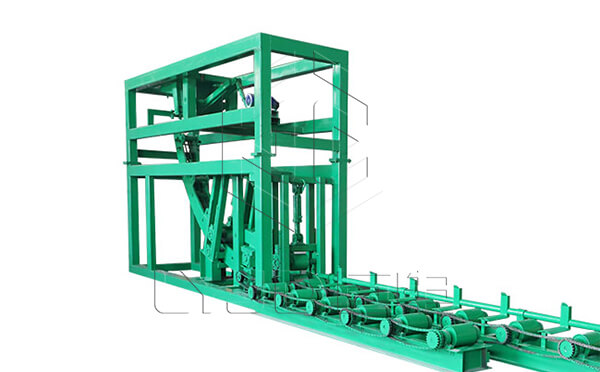

The billet roughing rolling machine is located behind the heating furnace, about 2m away from the heating furnace. The distance between the blanking machine and the first continuous rolling mill is determined by the length of the billet, generally not less than 8 meters, preferably 10 meters long. If the billet is longer, the distance between the billet opening machine and the first continuous rolling mill needs to be longer.

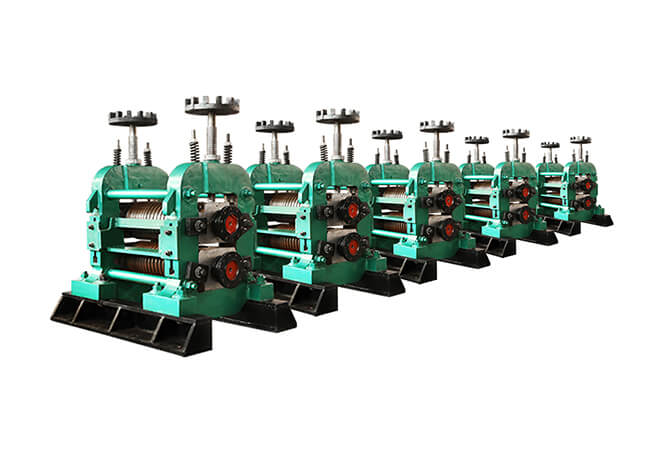

The distance between each continuous rolling mill is about 3 meters. Of course, the floor space of a rolling mill is determined by the number of rolling mills, which in turn is determined by the size of the finished product. Rolling finished products of different sizes requires different numbers of rolling mills through which the billet passes. Therefore, the total footprint of the tandem mill will be determined by the finished product size. Normally, at least 3 continuous rolling mills are needed in a small steel rolling production line to meet the production demand.

It is equipped with flying shears when passing through the water. The distance from the flying shears to the cooling bed is not less than 6 meters long, about 6-7 meters long.

The length of the cooling bed is determined by the length of the product. If conditions do not permit, the cooling bed may not be taken into account. The products produced can also be directly placed on the ground for natural cooling.

If the customer's plant area is limited, Judian can also provide customized plant design services, and can design the layout of the entire production equipment according to the customer's specific plant area. If you have questions about small scale steel rolling production line, you can consult online at any time, and we will provide you with reasonable and appropriate solutions as quickly as possible.

Please send us your request and we reply to you with in 24 hours.

Submit Request