Rolling mills are machines that roll the metal billets to various shapes with different thickness. In most steel plants, the steel rebar rolling mills are necessary to produce different products.

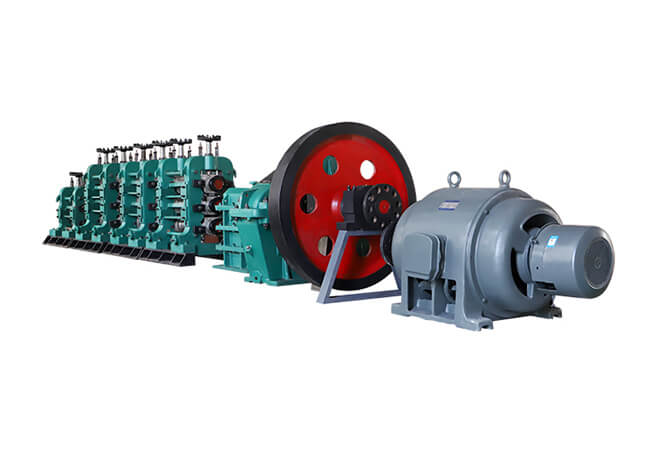

In general, a rolling mill consists of the main equipment and auxiliary equipment. The equipment that directly causes the plastic deformation of the rolled piece is called the main equipment, and it is also called the main machine column. Auxiliary equipment refers to different equipment other than the main machine column, which is used to complete a series of auxiliary processes. It includes shearing equipment, roller tables, coilers, straighteners, etc. There are many types of auxiliary equipment, and the degree of mechanization of the workshop is high, and the proportion of auxiliary equipment to the total weight of the entire workshop equipment is also greater.

Since the continuous development of the rolling industry and the wide variety of steel products, rolling mills can be classified according to their use, structure and arrangement.

Rolling mills that use steel ingots as raw materials to provide raw materials for finished rolling mills, including billet rolling mills, steel slab rolling mills, and slab rolling mills.

Billet rolling mill is also a rolling mill that provides raw materials for finished rolling mills, but the raw materials are not steel ingots. Generally, continuous and horizontal are available.

Section steel rolling mills include rail beams, large, medium and small rolling mills and wire rod mills.

According to the structure, we can divide the steel rebar rolling mills into rolling mills with horizontal rolls, rolling mills with mutually perpendicular rolls, and oblique and other special rolling mills.

This rolling mill is simple in structure and reliable in operation. It is driven by a DC motor and is used as a reversible two-roller roughing mill, which can reciprocally roll steel ingots into various rectangular billets. Two-high reversing mills can also be used for rolling rail beams and plate.

The continuous rolling unit is composed of several two-high stands driven by DC or AC motors in groups, which can produce billets and section steel, and it has the characteristics of high productivity.

The three-high rolling mill can roll the work pieces in two directions on the same stand, and the rolling mill does not need to be reversed. Several three-high rolling mills are driven by an AC motor through a reducer and a gear seat, which can realize reciprocating multi-pass rolling. The three-high rolling mill can be used for blanking and section steel production.

A four-high rolling mill consists of two upper and lower back-up rolls and two smaller work rolls. The smaller work rolls can reduce the contact area and reduce the rolling force, and the back-up rolls play a supporting role to reduce the bending of the work rolls and strengthen the rigidity of the rolling mill. In order to stabilize the work rolls, the work rolls are often shifted a small distance to the rolling direction to prevent the crossing of the centerlines of the rolls due to the bearing clearance. Four-high rolling mills are mostly used for strip rolling.

In order to adapt to the development of high-precision cold-rolled strip dimensions, multi-roll mills have appeared in six-high, twelve-high, and twenty-high mills. The twenty-high rolling mill can roll out thin strip steel and metal foil of several μ. In addition, in order to improve the rigidity of the rolling mill and simplify the structure of the rolling mill, various types of multi-roll rolling mills have emerged.

Rolls of vertical roll mill are vertical and can be used to process the sides of thick plates. In strip rolling, it is used for strip width control. In billet or section steel continuous rolling mills, vertical roller mills and horizontal rolling mills are alternately arranged on the continuous rolling line, which can eliminate the steel turning process in the pass system.

The axes of the two rolls of the inclined roll mill are arranged at an angle, and they rotate in the same direction and the rolled piece advances while rotating. It is used for seamless steel pipe piercing machine and leveling machine.

This type of rolling mill has the simplest layout, consisting of only one working stand and its drive and transmission system.

Several working machine bases are arranged in a row, driven by a motor through a common reducer and gear seat. The advantages of this arrangement are simple equipment, low cost and easy construction. The disadvantage is that the rolling speed cannot be increased with the increase of the length of the rolling mill, and it is gradually eliminated now.

The two working stands are arranged in a row according to the rolling direction of the rolled piece, and the rolled piece is rolled in each stand in turn, and each stand is individually driven, and the roll speed increases with the extension of the rolled piece length. It is commonly used in high productivity blooming mills and heavy plate mills.

Several working stands are arranged in a row, the number of stands is equal to the number of rolling passes, and the rolling mill is rolling in several stands at the same time. The continuous type is a modern rolling mill with high productivity, high degree of automation and high rolling speed.

The development trend of modern steel rebar rolling mills is continuous, automatic, and specialized, with high product quality and low consumption. Some new rolling methods suitable for continuous casting and rolling, controlled rolling, and rolling mills with various special structures to meet new product quality requirements and improve economic benefits are all under development.

Please send us your request and we reply to you with in 24 hours.

Submit Request