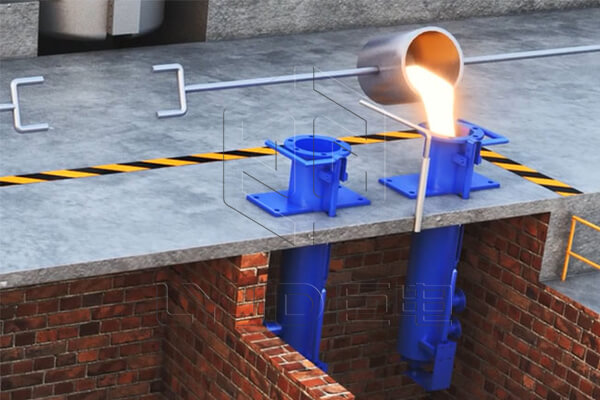

The production process of continuously casting high-temperature molten steel into a billet with a certain cross-sectional shape or a certain size specification is called continuous casting. The equipment required to complete this process is called continuous casting machine.

It must be suitable for the whole process of high-temperature molten steel from liquid to liquid and then to solid;

It must have a high degree of high temperature resistance, fatigue resistance and sufficient strength;

It must have high manufacturing and installation precision, easy maintenance and quick replacement, sufficient cooling and good lubrication, etc.

Generally, we name the continuous casting machine types according to the Running track of continuous casting stream, including vertical, vertical bending, arc, oval, and horizontal. Below, we will talk respectively.

The billet shell of the casting machine is cooled evenly and is not subject to bending and straightening, so it is not suitable for internal and surface cracks, which is conducive to the floating of inclusions, but the equipment is high in height, inconvenient to operate, high in investment costs, difficult in equipment maintenance and accident handling , The cross-section and fixed length of the casting slab and the drawing speed are limited, and the deformation of the slab belly is more prominent due to the high hydrostatic pressure of the casting slab.

The tundish, crystallizer, guide roll and dummy bar of the casting machine are distributed along the vertical line. The cutting machine is arranged horizontally, and the pouring and cooling and solidification are completed in the vertical direction. After being completely solidified, it is bent at 90° and enters the bending section, and the blank is released in the horizontal direction. The height of the casting machine is lower than that of the vertical casting machine, which is convenient for transportation. It is suitable for longer length product requirements, but due to the addition of a bending and straightening, it is easy to cause cracks.

It is divided into single-point straightening arc ccm, multi-point straightening arc ccm, and straight mold arc ccm.

Single-point straightening arc ccm: The height is lower than the vertical type and vertical bending type, so the weight of the equipment is light, the investment cost is low, and the installation and maintenance are convenient. The static pressure of the molten steel on the billet is small, which can reduce the inner column and segregation caused by the stock belly. It is beneficial to increase the casting speed and improve billet quality. However, during the solidification process of molten steel, non-metallic inclusions tend to focus in the arc, easily resulting in uneven distribution of impurities inside the slab.

Multi-point straightening arc ccm: The deformation rate of the solid-liquid interface is reduced. When the slab is straightened with a liquid core, no internal cracks will occur, which is beneficial to increase the casting speed.

Straight mold arc ccm: It has the advantages of vertical continuous casting machine, which is conducive to the floating of large inclusions and the average distribution of inclusions in steel. It is higher in height than vertical bending type, and the construction cost is low. But, the billet shell on the outer arc side of the billet is stretched, and the two-phase area is easy to cause crack defects. The equipment structure is complicated, and it is difficult to overhaul and repair.

Its advantages are that the height is greatly reduced compared with the arc continuous casting machine, the static pressure of molten steel is low, the amount of slab stock is small, the segregation of the internal crack center is improved, and the investment is saved by 20%-30% (compared to the arc shape). However, the inclusions in the molten steel in the crystallizer have almost no chance of floating, so the requirements for molten steel are strict.

The height of the equipment is the lowest. The quality of the slab is improved because of the secondary oxidation of molten steel. It is not subject to bending and straightening and is beneficial to prevent cracks. The maintenance of the equipment is simple, and the accident handling is convenient. But the separation of the connection between the tundish and the crystallizer costs more, and it is difficult to lubricate between mold and billet. In addition, the mold does not vibrate during billet casting. Thus, it is suitable for casting small billets smaller than 200mm.

The continuous casting billets hot charging process refers to the method that the billets produced by the continuous casting machine are not cooled, directly drawn into the heating furnace for heating in a hot state, and then rolled. The continuous casting billet direct rolling process means that the high-temperature billet coming out of the casting machine is directly sent to the rolling mill for rolling without heating or only slightly supplementary heating of the edges.

1) Simplify the production process and shorten the production cycle;

2) Small footprint;

3) Less investment in fixed assets;

4) High yield of metal;

5) Good performance of steel;

6) Less energy consumption;

7) The factory capacity is greatly reduced;

8) Good working conditions, easy to realize automation.

Please send us your request and we reply to you with in 24 hours.

Submit Request