Improving the output and quality of continuous casting billets is the common focus of steel plants. There are many factors that affect the quality of the billet of the continuous casting machine, among which the secondary cooling control is very critical, and choosing an appropriate secondary cooling control method is a prerequisite for ensuring the quality of the billet. Then, how to avoid the continuous casting billet defects during the secondary cooling?

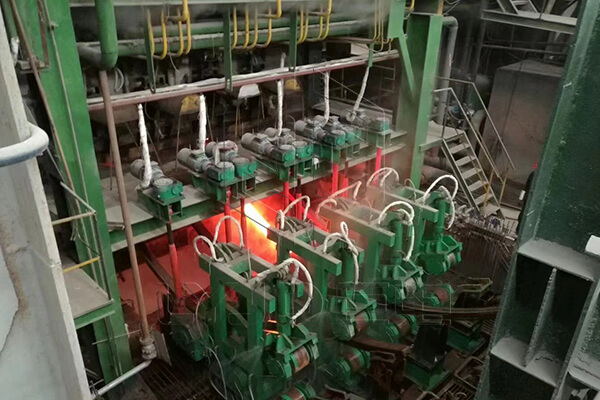

The secondary cooling effect of the continuous casting machine has a very important influence on the quality of the billet, and the billet defects related to the secondary cooling are mainly manifested in the following types.

In the secondary cooling zone of the continuous casting machine, if the cooling between the sectors is uneven, it will cause periodic changes in the surface temperature of the billet, causing the temperature of the billet to rise, etc., resulting in repeated phase changes in the shell of the billet. At the same time, due to the existence of strain, intermediate cracks along the columnar grain boundaries will appear between the surface and the interior of the billet, thus forming subcutaneous cracks.

Due to the unsatisfactory secondary cooling, when the billet is being straightened, its surface temperature is just in the "brittle zone", and under the action of the straightening force, phenomena such as surface transverse cracks may appear.

Due to the amount of secondary cooling water and other reasons, the cooling effect is not good, the surface temperature of the billet is too high, and the high temperature strength of the steel is low. Under the action of the hydrostatic pressure, the solidified shell of the billet will deform, resulting in bulging.

If the four sides of the billet are not cooled uniformly, the four sides of the billet will shrink asymmetrically and the billet will be twisted.

The control of the secondary cooling will affect the effect of the secondary cooling, and then affect the quality of the billet. The ideal secondary cooling effect should make the surface temperature of the billet drop uniformly along the casting direction, and at the same time make the straightening point of the billet avoid the brittle area of its steel type. In order to produce an ideal secondary cooling effect, the control of the secondary cooling water volume is particularly important.

Install a thermometer in each secondary cooling section of the billet to test the stable surface temperature of the billet, and control and adjust the amount of water according to the difference between the designed theoretical target temperature and the measured surface temperature of the billet. The advantage of this method is that it is simple and easy to operate, but due to the high temperature and humidity in the secondary cooling zone, there are oxide scales and water mist on the surface of the billet, which affects the accuracy of temperature measurement, which will cause errors during use and is not ideal.

This control method is to formulate the target control surface temperature suitable for each steel type, find out the actual temperature of the billet surface, and at the same time formulate the corresponding relationship parameters between the actual temperature and the target control surface temperature, and put the relevant parameters in advance. In the control computer, in the actual production, the corresponding corresponding parameters are selected according to different steel types, and the cooling water volume is configured according to the casting speed to control the secondary cooling effect. This method is conducive to improving the quality of the billet, but the control method is static control, which is not conducive to the production of multiple varieties and high rhythm.

Combined with the steel type, the casting speed of the billet and the corresponding casting state, the surface temperature of the billet is calculated regularly by the mathematical model, and dynamically compared with the preset target surface temperature considering the principle of secondary cooling water distribution. Calculate the amount of cooling water in each sector of the secondary cooling zone based on the difference between them, so as to ensure that the surface temperature of the billet is consistent with the target surface temperature. The basis for determining the target surface temperature is based on the water distribution for the best secondary cooling effect. The optimal water distribution for the secondary cooling effect refers to the optimal temperature arrangement produced by the optimized water volume allocation of each cooling sector in the secondary cooling zone, in order to achieve the best cooling effect.

Among the above three control methods, the target surface temperature dynamic control method is the best. This method not only considers the steel type, the specification and size of the billet, the temperature at the nozzle of the tundish, the casting speed and many other factors, but also dynamically realizes the secondary cooling water flow. The optimized configuration ensures that the surface temperature of the billet coincides with the target surface temperature, thereby producing the best secondary cooling effect to improve or improve the quality of the billet.

Please send us your request and we reply to you with in 24 hours.

Submit Request