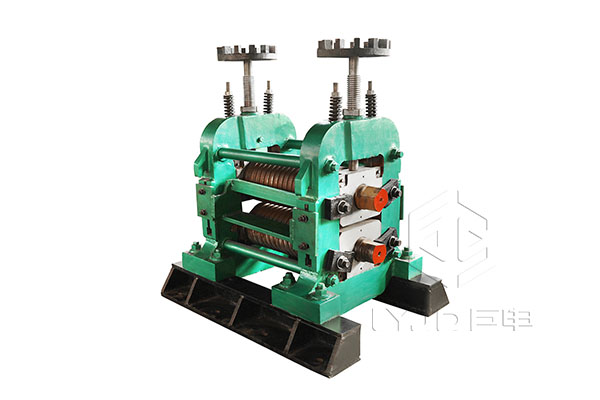

In the foundry factories, we can definitely find the roughing mill. It is usually used to produce rebar, section steel, wire rods, and other steel products. Today, we will talk with you about it.

A roughing rolling mill is a machine used in the metalworking industry to shape and reduce the thickness of metal ingots or billets into smaller, more manageable forms. Its primary purpose is to prepare the metal for further processing by reducing its thickness and improving its surface quality.

The mill typically consists of a series of rolling stands that progressively reduce the thickness of the metal as it passes through each stand. The metal is fed into the mill and passed through a series of rollers that apply pressure to the metal, reducing its thickness and elongating it.

The roughing mill is typically the first stage in a larger metalworking process, with the metal being further shaped and processed through additional rolling mills, forging presses, or other equipment. The final product may be a sheet, plate, bar, or other form of metal that is ready for use in various industrial applications.

The primary function of a roughing mill is to reduce the thickness of metal ingots or billets and prepare them for further processing. It achieves this by applying pressure to the metal as it passes through a series of rolling stands, progressively reducing its thickness and elongating it.

In addition to reducing the thickness of the metal, the roughing mill also improves the surface quality of the metal by removing any surface imperfections and producing a more uniform surface finish. This is important because it ensures that the metal is of consistent quality and is ready for further processing.

The roughing mill is typically the first stage in a larger metalworking process, with the metal being further shaped and processed through additional rolling mills, forging presses, or other equipment. The final product may be a sheet, plate, bar, or other form of metal that is ready for use in various industrial applications.

The size of the billets that a roughing mill can roll depends on the specific design and capacity of the mill. Roughing mills are typically designed to handle a wide range of billet sizes, from small billets that are a few inches in diameter to large billets that are several feet in diameter.

Its capacity is typically measured in terms of the maximum width and thickness of the billet that it can handle. For example, it may be designed to handle billets with a full width of 12 inches and a maximum thickness of 4 inches.

The exact size of the billet that a roughing mill can roll will also depend on other factors such as the type of metal being rolled and the specific rolling process being used. For example, some metals may be more difficult to roll than others and may require special equipment or processing techniques to achieve the desired results.

In general, however, roughing mills are designed to handle a wide range of billet sizes and can be customized to meet the specific needs of a particular metalworking operation.

A roughing mill is a machine used in the metalworking industry to reduce the thickness of metal ingots or billets and prepare them for further processing.

Please send us your request and we reply to you with in 24 hours.

Submit Request