In the steel plant, we can always find the continuous casting machine and rolling mill. They are the necessary equipment to produce rebar, wire rod, and other steel products. However, do you know what we should know working with them? Now, Judian will introduce the details about the continuous casting machine and rolling mill to you.

Continuous casting machine, also called CCM, is advanced equipment that realizes continuous casting. In this process, the surface of the liquid steel and the billet can be dynamically steady. On the one hand, the liquid steel solidifies against the mould walls, and on the other hand, the billet solidified is pulled out from the bottom of the mould at a steady speed. Thus, the interface of the liquid steel and the billet will be at a relatively constant position as time goes on.

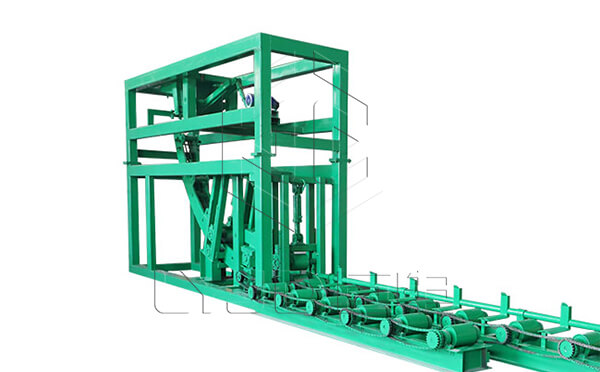

The rolling mill is divided into two types: semi -finished and finishing rolling mill. The semi -finished rolling mill includes: various types of first rolling machines, billet rolling machines, and small and medium -sized opening rolling machines. The finishing rolling machine includes: steel rolling machine, steel plate rolling machine, steel pipe rolling machine, and special use rolling mill.

1. Product type: At present, more than 100 steel types have been cast. We need to select the next step according to the type and quality of the product.

2. Casting Section: The size and shape of the casting section mainly determine the ability of the rolling machine and the quality requirements of the rolling machine. The production section of the casting machine should meet the requirement of the rolling mill. Small casting machines mainly match the 650, 500, or 400 rolling mill to produce profiles and wires. Its typical billet section is: 650 rolling machine, 140 to 220mm square blank, casting ruler 2.8 to 3.2m; 500/350 rolling machine, 120 to 140mm square blank, fixed ruler 1.4 to 1.6m; 400/300 rolling machine, 90-120mm square blank, a fixed ruler 1.4 to 1.6m.

If the cutting surface of the casting blank is greater than 160mm blank, it is mainly used for section steel such as rails, work beams, and slot steel.

3. Compression ratio: Generally speaking, the small section of the supply of the blank can reduce the number of heating times and rolling channels, and improve the productivity of rolling machines and save energy. However, the section should be based on the premise of satisfying a certain compression ratio. The so -called compression ratio refers to the ratio of the horizontal area of the cast blank to the rolling material. In order to ensure that the internal tissue of rolling materials is dense, it has good mechanical properties, and different products require different compression ratios. When the compression ratio is 3, the mechanical properties required by general products can be achieved; when the compression ratio is 4, the product has good physical properties, which can uniformly the central tissue; , Uniformly the tissue of the steel and obtain good mechanics and physical properties.

4. Smart tolerance: For square blanks, the shape must be regular. The deviation of the two diagonal lines of the section is less than 2.5 to 3 %, and the deviation of the corner of the section is about 2°. If the diamond shape is severe, it may cause stacked steel when pushing the blank, or the blanking of the blanking into the pore type when it is rolled.

Please send us your request and we reply to you with in 24 hours.

Submit Request