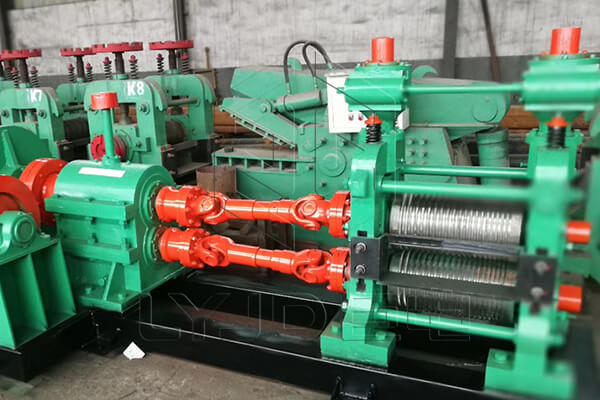

The wire rod mill, as the name suggests, is a rolling mill specially used for rolling wire rods. The wire rod is the product with the smallest cross-sectional size of the profile. It is rolled from the billet to the finished product, and the total elongation coefficient is large. The rolled piece is often only rolled once on each rolling mill. Therefore, the wire rod mills are the rolling mills with the largest number of stands and the thinnest division of labor among hot-rolled profiles.

High-speed, continuous rolling is the development direction of wire rods and bar mills. The products of small rolling mills and wire rod mills are small in section and light in weight. Only by increasing the rolling speed, can we increase the output. Because high-speed rolling can not only improve production efficiency but also use continuous casting slabs with larger cross-sections during rolling. According to the survey, the rolling speed of the highest practical wire rod mill has reached 120m/s at present.

After comparing many layout forms and process characteristics of small-scale and wire rod mills, it is concluded that the horizontal type, parallel type, chess-type, and semi-continuous type are not as good as the continuous type and are more suitable for the requirements of small-scale and wire rod rolling. The temperature drop of the slender rolled piece is fast, and the rolling time is the key. Continuous rolling not only shortens the rolling time but also reduces the temperature difference between the head and the tail of the rolled piece. In theory, it can realize the constant temperature rolling of each stand. The continuous rolling mill is the easiest to operate, employs the least number of people, and has the highest mill efficiency. Due to the pursuit of high-speed and continuous rolling for many years, small and wire rod mills have developed rapidly, and at the same time promoted the progress of rolling technology.

The wire rod rolling mill production line can realize full continuous and high-speed rolling, and the highest rolling speed can reach 120m/s.

Optimize the mill layout for the wire rod production line. The intermediate roughing and intermediate rolling are alternately arranged horizontally and vertically, and there is a pre-finishing rolling in front of the finishing mill.

Using a high-speed wire rod mill can increase the cross-section of the feed billet. In this way, it can not only meet the needs of the upstream continuous casting machine to improve the productivity and quality of the slab, but also increase the coil weight, and improve the productivity and yield of the wire rod mill.

The high-speed wire rod mill has a wide range of final products. It can produce wire rods with diameters from 6mm to 30mm.

Digitalize the automatic control system. And it improved the control precision, reliability, and ease of operation of the rolling process.

The rolling start temperature is about 950°C. This requirement is met when selecting the stiffness of the rough and medium rolling stand and the capacity of the main motor, to achieve overall energy saving and reduce metal burning loss.

Because of the rapid development of infrastructure all over the world, wire rods of various specifications are in short supply. The continuous iteration and innovation of the wire rod mill process have therefore become inevitable.

Luoyang Judian is a professional manufacturer of wire rod mills. With more than 10 years of experience, we have provided products to more than 100 customers around the world. If you have any questions about wire rod mills, please feel free to consult us. We will solve your problem as quickly as possible.

Please send us your request and we reply to you with in 24 hours.

Submit Request