In many steel plants, we can see a lot of steel rolling mills working. Among these rolling mills, there are various types. So, what are the different types of steel rolling mills? In this article, Luoyang Judian will show you the types of steel rolling mills.

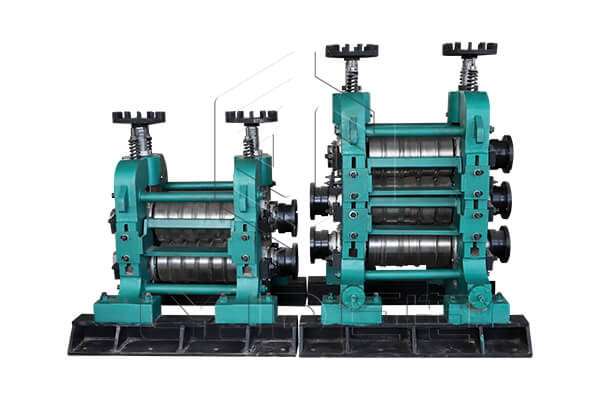

A steel rolling mill is a machine that rolls the preheated steel billet or steel rod into different shapes and sizes of steel products. Generally, it contains several parts, including rolls, roll bearings, rolling mill stands, rolling mill rail seats, gearing, auxiliary equipment, etc.

Rolls: The main working parts and tools on the rolling mill that cause continuous plastic deformation of metals.

Bearing: It supports the roll and keeps the roll in a fixed position in the stand.

Rolling mill stands: It consists of two "archways" to install the roll chock and roll adjustment device. And, it needs to have sufficient strength and rigidity to withstand the rolling force.

Gearing Device: Include a motor, reducer, gear seat, and connecting shaft. The gear seat distributes the transmission torque to two or several rolls.

Rolling mill rail seat: To install the rack and fix it on the foundation, also known as the base plate. Bear the gravity and overturning moment of the working machine base, and at the same time ensure the accuracy of the installation size of the working machine base.

If you have no idea about how to classify steel rolling mills, you can refer to the specifications of the final products. It may be helpful. Below are the four main types of rolling mills.

Cluster mills: A cluster rolling mill is a special type of four-high rolling mill. The two working rolls are backed up by two or more of the larger backup rolls which are able to roll hard materials.

Continuous rolling mills: Several stands of the continuous rolling mill are arranged in a row according to the rolling direction. The workpiece is rolled and deformed in several stands at the same time. The rolling speed of each stand increases with the length of the rolled piece, and the metal is kept equal second flow in each mill.

Planetary rolling mills: The planetary rolling mill is a rolling mill composed of one or two supporting rolls and many planetary rolls (work rolls) around the supporting rolls. Due to the complex structure, large vibration and noise, unstable production, low rolling speed, low thickness accuracy, and poor surface quality, the planetary rolling mill develops slowly.

Two, three, four high mills: It’s up to the stands amount. Two-high rolling mills or four-high rolling mills are more frequently seen in steel plants.

According to the number of rolls, the two high steel rolling mills and four high steel rolling mills are commonly and widely applied in steel plants.

The structure is simple and the application is extensive, including reversible and irreversible. The former includes preliminary rolling mills, rail and beam rolling mills, and plate rolling mills. While, the irreversible type includes a billet continuous rolling mill, a stacked sheet rolling mill, a sheet or strip cold rolling mill, a skin tempering mill, etc.

The rolled piece is alternately rolled from the upper and lower roll gaps to the left or right and is generally used as a section steel rolling mill and a rail beam rolling mill.

The roll diameter of this steel rolling mill is small. In addition, the rolling pressure is borne by the backup roll with a large diameter. The advantages of this kind of steel rolling mill are relatively high rigidity, large reduction, small rolling force, and can roll of thinner plates. There are two types of reversible and continuous rolling, widely used in plate rolling mills, strip hot or cold rolling mills and temper mills.

According to the function, there are three main types of steel rolling mills. Roughing rolling mills, intermediate rolling mills, finishing rolling mills.

Steel ingots, especially large ones, usually cannot be directly rolled into steel products of the required size. Therefore, we need to roll ingots into billets (billet opening), and then roll them into finished products. We call the heavy-duty rolling mill used to process steel ingots into billets roughing rolling mills. The roughing rolling mill usually refers to the blooming mill and the slab mill.

The intermediate rolling mill provides a suitable shape and size of the rolled piece for the finishing mill. Therefore, the rolls of intermediate rolling mills must have good thermal crack resistance and wear resistance at the same time. And, because the pass is deep, the rolls are also required to have certain strength and toughness.

The finishing mill is the core part of the steel rolling production line and the key process to determining final product quality. It follows after the intermediate rolling mill.

The finishing rolling mill has the characteristics of light weight, simple structure, easy to change rolls, small maintenance workload, and compact unit arrangement.

The development trend of modern rolling mills is continuous, automated, and specialized, with high product quality and low consumption. Some new rolling methods suitable for continuous casting and rolling, controlled rolling, and rolling mills with various special structures to meet new product quality requirements and improve economic benefits are under development.

Please send us your request and we reply to you with in 24 hours.

Submit Request