Currently, there are many types of continuous casting machines and methods. And, each of them has the specific characters. Today, Judian will introduce the common types of continuous casting machine and methods to you.

The continuous casting production process usually has the following requirements for the equipment:

1. The equipment must adapt to the whole process of high temperature molten steel changing from liquid to liquid-solid and back to solid;

2. The equipment must have sufficient high temperature resistance, fatigue resistance and sufficient strength;

3. The installation process is simple and easy to operate. Easy maintenance and quick replacement, adequate cooling and good lubrication, etc.

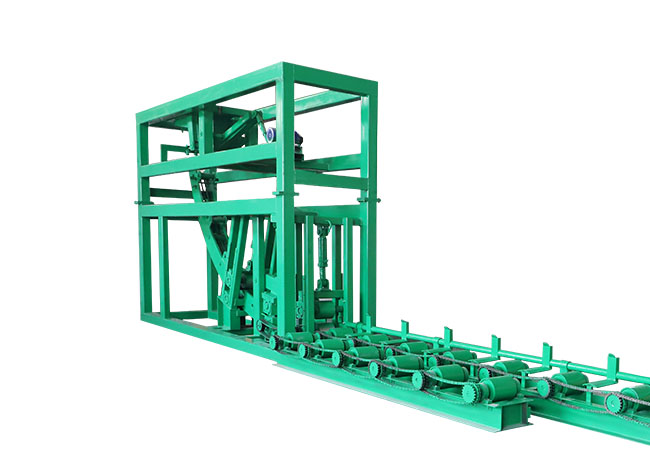

In the steel rolling production line, during continuous casting production, the continuous casting machine can be divided into vertical continuous casting machine, vertical bending continuous casting machine, arc continuous casting machine, elliptical continuous casting machine and horizontal continuous casting machine according to the running trajectory of the process. casting machine.

Vertical continuous casting machine: The shell of the casting machine is cooled evenly and is not affected by bending and straightening, so it is not suitable to produce internal and surface cracks, which is conducive to the floating of inclusions, but the equipment height is large, the operation is inconvenient, the investment cost is high, and the equipment Maintenance and accident handling are difficult, the slab section, fixed length and pulling speed are limited, and the slab groin deformation is prominent due to the large hydrostatic pressure of the molten steel.

Vertical bending type continuous casting machine: The tundish, mold, guide roller and dummy bar of the casting machine are distributed along the vertical line. The cutting machine of the tension leveling machine is arranged horizontally. The casting and cooling and solidification are completed in the vertical direction. After complete solidification, it is bent by 90°, enters the bending section, and unloads the billet in the horizontal direction. The height of the casting machine is lower than that of the vertical type, which is convenient for transportation. , which can meet the requirements of longer fixed length, but due to the addition of one bending and straightening, one will cause cracks.

Arc-shaped continuous casting machine: divided into single-point straightening arc-shaped continuous casting machine, multi-point straightening arc-shaped continuous casting machine, straight mold arc-shaped continuous casting machine.

Oval continuous casting machine: its advantages are that the height is greatly reduced compared with the arc, the hydrostatic pressure of the molten steel is low, the amount of the billet is small, the segregation of the internal crack center is improved, and the investment is saved by 20%-30% (compared to the arc) . However, the inclusions in the molten steel in the mold have almost no chance of floating, so the requirements for the molten steel are strict.

Horizontal continuous casting machine: The height of the equipment is relatively low, the molten steel is secondary oxidized, the quality of the casting billet is improved, and it is not affected by bending and straightening, which is conducive to preventing cracks. The equipment is simple to maintain and easy to handle accidents, but the separation between the tundish and the mold is expensive, and the lubrication between the mold and the billet is difficult. The mold does not vibrate when the billet is drawn.

This is our knowledge sharing about continuous casting machines today, I hope it can be helpful to you. Welcome to Luoyang Judian, let us provide you with more services.

Please send us your request and we reply to you with in 24 hours.

Submit Request