Wire production process

Wire refers to hot-rolled round steel with a diameter of 5-22mm or the section steel corresponding to this section. Because it is delivered in coil form, it is also commonly referred to as wire.

The wire is characterized by small cross-section and large length, and requires high dimensional accuracy and surface quality.

According to the different types of rolling mills, it can be divided into high-speed wire rod production lines and ordinary wire rod production lines.

High-speed wire rod production lines are rolled on high-speed wire rod mills. The production rhythm is fast and the disk volume is large. The packaging is usually compact and beautiful.

High-speed wire rod refers to the wire rod rolled by "high-speed non-twist mill". The rolling speed is 80-160m/s, the weight of each plate is 1.8-2.5 tons, and the dimensional tolerance can reach 0.02mm.

During the rolling process, the process parameters can be adjusted especially on the cooling line to ensure the different requirements of the product.

Ordinary wire refers to the wire that is rolled by "ordinary rolling mill". The rolling speed is 20-60 m/s, and the weight of each disc is 0.4-0.6 tons.

During the rolling process, air cooling can only be carried out through the cooling line. Or air-cooled to ensure product performance. Ordinary wires are rolled by ordinary rolling mills, and generally the weight of the coil is small.

Its production process is as follows:

Billet Shipment → Batch Weighing → Inventory → Loading Before Furnace Loading → Billet Quality Check → Single Weighing → Heating → Rough Rolling → Cutting Head and Tail → Middle Side Rolling → Middle Rolling → Pre-insertion → Cutting Head Tail Tail → Rolling → Water Cooling → Spinning in Circulation → Bulk Cooling → Collecting Coils → Cutting Heads and Tails → Pressing and Bundling → Weighing and Marking → Storage

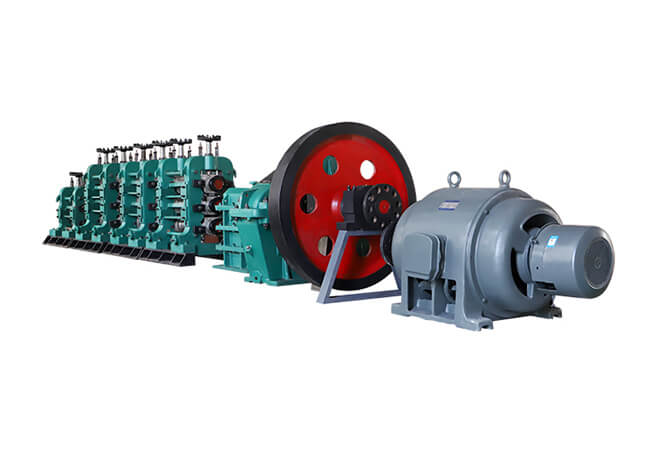

Regarding the wire rod mill, we should consider the following issues when purchasing.

Determine the main motor electric control device, so that each section of the rolling mill can realize tension-free or micro-tension rolling, and improve the product quality and rolling efficiency of the wire rod.

Control the rolling and cooling process of the rebar. Guaranteed to obtain the best product quality.

A high pressure descaling facility can be considered before the rolling mill to improve the surface quality of the final product.

Luoyang Judian is a manufacturer of rolling mills. If you have requirements, you can customize our products.

Or have any questions about the rolling mill, you can consult us.

Please send us your request and we reply to you with in 24 hours.

Submit Request