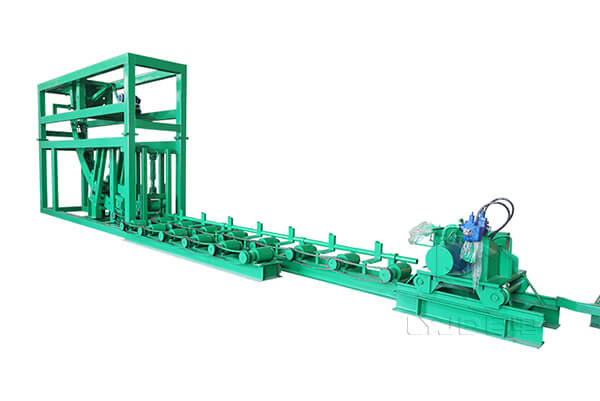

Continuous casting machine is the general term for complete sets of equipment that can realize the above process. In a narrow sense, the continuous casting machine includes casting equipment, continuous casting machine body equipment, cutting area equipment, dummy bar collection and conveying equipment, etc. So, what is the function of continuous casting machine in the continuous casting and rolling line?

Continuously pour high-temperature molten steel into one or a group of water-cooled copper crystallizers. The molten steel gradually solidifies along the periphery of the crystallizer into a billet shell. The slab is pulled out and cooled by spraying water in the secondary cooling zone to completely solidify the slab, and cut to length by the cutting device according to the steel rolling requirements. This process of casting high-temperature liquid steel directly into billets is called continuous casting.

Continuous casting machines can be classified in various forms. According to the structural shape, the continuous casting machine can be divided into vertical continuous casting machine, vertical bending continuous casting machine, arc continuous casting machine with a straight line segment, arc continuous casting machine, multi-radius oval continuous casting machine, and horizontal continuous casting machine. With the development of continuous casting technology, research on wheel continuous casting machines, especially thin slab continuous casting machines, has been carried out.

If it is distinguished according to the size and shape of the section cast by the continuous casting machine, the continuous casting machine can be divided into a slab continuous casting machine, a billet continuous casting machine, a bloom continuous casting machine, a round billet continuous casting machine, and a special-shaped section Continuous casting machines and thin slab continuous casting machines. The billet continuous casting machine also includes the rectangular billet continuous casting machine. Usually, the cast slab with a casting cross-section or an equivalent cross-sectional area greater than 200×200mm is called a bloom, and a billet with a cross-section or an equivalent cross-sectional area smaller than 160×160mm is called a billet. , the aspect ratio is greater than 3 rectangular blanks are called slabs.

According to the number of billets that a continuous casting machine can cast simultaneously, it can be divided into single-flow, double-flow, or multi-flow continuous casting machines.

After the molten steel produced by the converter is refined in the refining furnace, the molten steel needs to be cast into billets of different types and specifications. The continuous casting section is the production process of continuously casting refined molten steel into billets through the continuous casting machine. The main equipment includes a rotary table, a tundish, a crystallizer, and a straightening machine.

For the continuous casting process of the continuous casting machine, the non-sinusoidal vibration technology of the mold has a significant effect in increasing the casting speed, improving the surface quality of the casting slab, and reducing the leakage rate. This technology can not only increase the casting speed of the continuous casting machine, increase productivity, reduce leakage, and make the production of the continuous casting machine stable, but also provide high-quality casting billets for rolling and improve the quality of rolled products.

The ladle containing the refined molten steel is transported to the turret. After the turret is rotated to the pouring position, the molten steel is poured into the tundish, and the tundish distributes the molten steel to each crystallizer through the nozzle. The crystallizer is one of the core pieces of equipment of the continuous casting machine, which makes the casting shape and quickly solidifies and crystallizes. The tension leveler and the crystallization vibration device work together to pull out the casting in the crystallizer and cut it into a certain length after the billet gets cool.

Continuous casting automation control mainly includes control technologies such as continuous casting machine throwing roll speed control, crystallizer vibration frequency control, and fixed-length cutting control. The continuous casting process requires that the continuous casting machine can discharge the slab at a high temperature, and the slab has a high surface quality and internal quality.

Not only that but the continuous casting machine is also required to have stable high productivity and high casting speed to meet the needs of high-speed rolling. It can be seen that the non-sinusoidal vibration technology of the mold is the key technology of continuous casting and rolling, which needs to be mastered correctly by the user.

The continuous casting machine is the key technology in the continuous casting and rolling process. Because it simplifies the production process, improves production efficiency and metal yield, saves energy consumption, greatly reduces the production cost, and has the advantages of good billet quality and other advantages, it has been developed rapidly. In today's steelmaking enterprises, whether it is long-process steelmaking or short-process steelmaking, the function of continuous casting machine is not to be ignored.

Luoyang Judian is a professional manufacturer of continuous casting machines and supporting equipment. With 12 years of production experience, we can meet the specific needs of different customers. If you have any questions about the continuous casting machine, please feel free to contact us, and we will do our best to solve your problems.

Please send us your request and we reply to you with in 24 hours.

Submit Request