When designing a steelmaking plant, the first priority is the selection of the steel billet continuous casting machine (CCM). A suitable CCM should be determined according to the product plan, product quality, and reduction of construction investment. Proper selection of CCM will create conditions for future management and high efficiency and high quality production of continuous casting machine.

There are many kinds of continuous casting machines, such as vertical continuous casting machine, arc continuous casting machine and so on. They all have their own advantages and disadvantages.

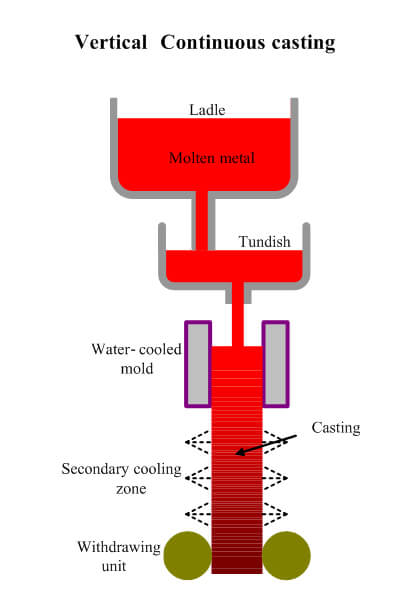

The main parts of the vertical continuous casting machine from the tundish to the cutting station are arranged in a vertical line. The entire fuselage stands on the ground level of the workshop or is arranged in a deep pit underground.

Advantage

Shortcoming

The curved continuous casting machine uses a curved crystallizer with a certain radius of curvature. Its crystallizer, secondary cooling device and tension straightening device are all arranged on a quarter arc of a circle with a certain radius. The slab is bent when it is solidified in the mold, and the slab with the liquid core is pulled out from the mold, runs along the arc track, continues to spray water for cooling, completes solidification at a quarter of the arc, and then straightens and pull out.

Advantage

Shortcoming

1. The production capacity of the continuous casting machine should match the production capacity of the steel melting furnace. In order to develop the production potential of steelmaking, the production capacity of the continuous casting machine should be 10-20% rich.

2. Meet the requirements of steel grade and rolling section specification. According to the statistical data of production practice, the current application of vertical, vertical bending and arc continuous casting machines can meet the requirements of pouring ordinary carbon steel, low alloy steel, alloy steel and different specifications of sections, but the arc continuous casting machine It is the most widely used (accounting for more than 60% of construction continuous casting machines).

3. Meet product quality requirements. The quality of the slab mainly includes two aspects, one is the internal cracks and segregation of the slab, and the other is the purity of the slab. Taking the above two factors into consideration, the arc continuous casting machine is still an ideal model. If auxiliary measures such as refining outside the furnace and non-oxidizing pouring are adopted, the curved continuous casting machine can fully meet the requirements of product purity. In order to completely solve the shortcoming of inclusion accumulation in the inner arc of the arc continuous casting machine, there is a new development trend to build a vertical curved continuous casting machine with a straight mold and a vertical section (2-3m).

4. Reduce construction investment and equipment manufacturing costs.

Regarding the choice of models, there is no uniform standard. Combined with the factory's product plan, comprehensive consideration should be given to productivity, product quality, casting machine height, and investment. The construction of steel billet continuous casting machines should be regarded as a systematic project. In the upstream of the continuous casting machine, it should be considered that steelmaking should have a guarantee system for continuous casting to provide qualified molten steel (such as refining outside the furnace), and in the downstream of the continuous casting machine, the possibility of hot delivery, hot charging and direct rolling of the casting billet should be considered and rolling product quality assurance system.

Please send us your request and we reply to you with in 24 hours.

Submit Request