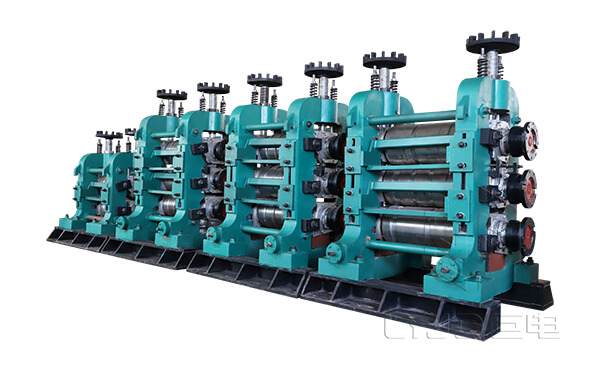

If you are looking for a way to produce high-quality reinforced steel bars, you might want to consider investing in a rebar rolling machine. A rebar rolling machine is a device that bends and cuts steel bars into various shapes and sizes, such as coils, rings, stirrups, and spirals. Rebar rolling machines are widely used in the construction industry, especially for concrete reinforcement projects.

In this blog post, we will explain what a rebar rolling machine is, how it works, and what types of rebar rolling machines are available in the market. In addition, we will introduce some basic features and functions of a rebar rolling machine, as well as some tips on how to choose and operate one. We hope this guide will help you get started with your rebar rolling business.

A rebar rolling machine, also known as a rebar bender or a rebar cutter, is a machine that can process steel bars into different shapes and lengths. Rebar rolling machines are widely used in the construction industry, especially for building bridges, tunnels, highways, and other structures that require reinforced concrete.

- A feeding system that transports the steel bars from the storage area to the bending and cutting area.

- A bending system that uses rollers, gears, and hydraulic cylinders to bend the steel bars into different angles and shapes.

- A cutting system that uses blades, shears, or saws to cut the steel bars into the desired lengths.

- A control system that allows the operator to set the parameters and monitor the working status of the machine.

- A safety system that protects the operator and the machine from accidents and damages.

- To produce various types of reinforced steel bars, such as round bars, square bars, flat bars, angle bars, etc.

- To produce different shapes and sizes of reinforced steel bars, such as coils, rings, stirrups, spirals, etc.

- To produce reinforced steel bars with high precision and accuracy, according to the specifications and standards required by the customers or the projects.

- To save time, labor, and material costs, by reducing wastage and increasing the efficiency of the production process.

The working principle of a rebar rolling machine is simple: it uses hydraulic or electric power to drive the rollers, blades and dies that process the steel bars. The steel bars are fed into the machine through the feeding system, which can be manual or automatic. The feeding system can also adjust the position and direction of the steel bars to ensure they are aligned with the bending or cutting system.

The bending system uses rollers or mandrels to bend the steel bars at a certain angle and radius. The bending system can also rotate the steel bars to create different shapes and patterns. The cutting system uses blades or shears to cut the steel bars at a certain length. The cutting system can also be synchronized with the bending system to produce continuous or segmented steel bars. The shaping system uses dies or molds to shape the steel bars into various forms, such as stirrups, hoops, spirals, etc. The shaping system can also be combined with the bending and cutting systems to produce complex shapes and sizes.

The control system monitors and controls the operation of the machine. It can set the parameters of the machine, such as speed, pressure, angle, radius, length, etc. It can also display the status of the machine, such as temperature, voltage, current, etc. The control system can also detect and correct any errors or faults that may occur during the operation of the machine.

There are different types of rebar rolling machines available in the market, depending on their functions and features. Some of the common types are:

- Manual rebar rolling machines: These are simple and low-cost machines that require manual operation and adjustment. They are suitable for small-scale projects or occasional use.

- Semi-automatic rebar rolling machines: These are more advanced and efficient machines that have some automatic functions and settings. They are suitable for medium-scale projects or frequent use.

- Fully automatic rebar rolling machines: These are high-end and sophisticated machines that have full automation and intelligence. They are suitable for large-scale projects or continuous use.

If you are planning to buy a rebar rolling machine, here are some tips that might help you make a wise decision:

- Consider your production needs and budget. You should choose a rebar rolling machine that suits your production capacity, quality requirements, and budget. It would be best if you also considered the maintenance costs and the availability of spare parts and technical support.

- Compare different models and brands. You should compare the features, functions, performance, and prices of different models and brands of rebar rolling machines. You should also check the reviews and feedback from other customers or experts.

- Test the machine before buying. You should test the machine before buying it, to make sure it works properly and meets your expectations. You should also ask for a warranty and a service contract from the seller.

- Follow the instructions and safety rules. You should follow the instructions and safety rules provided by the manufacturer or the seller when operating the rebar rolling machine. You should also wear protective equipment and avoid touching or approaching the moving parts of the machine.

A rebar rolling machine is a useful tool for producing reinforced steel bars for various construction projects. It can bend and cut steel bars into different shapes and sizes with high precision and efficiency. However, it is important to choose and operate a rebar rolling machine carefully, to ensure its quality and safety. We hope this blog post has given you some basic information and tips on how to use a rebar rolling machine. If you have any questions or comments, please feel free to contact us.

Please send us your request and we reply to you with in 24 hours.

Submit Request