Section steel rolling mills refer to the rolling mills that produce various section steel. It mainly includes rail beam rolling mill (roll diameter is generally 750~950mm), large rolling mill (roll diameter is generally 550~650mm), medium rolling mill (roll diameter is generally 350~500mm), small rolling mill (roll diameter is generally 250~300mm), wire rod mill (roll diameter is generally 250mm or less).

There are several production methods of section steel, such as hot rolling, welding, and cold bending. Among them, hot-rolled section steel has the advantages of high efficiency, less energy consumption, and low cost. In addition, the hot-rolled section steel is suitable for large-scale production. It has become the main method of section steel production.

There are mainly two types of hot rolling production of section steel, the pass method and the universal method.

The pass system of a section steel rolling mill can be divided into two categories according to the shape:

(1) Simple section pass: including box pass, diamond pass, hexagon pass, ellipse pass, square pass, and round pass.

(2) Special-shaped section pass: generally, there are I-shaped passes, slot-shaped passes, rail-shaped passes, T-shaped passes, etc.

The passes used in rolling by the pass method are composed of a pair of grooves on the rolling set. Therefore, in the same pass, the diameter of the rolling wheel has obvious changes. There are obvious differences in the line speed of the point, especially when rolling profiles with special-shaped cross-sections. The speed difference is greater when the closed pass or diagonal pass is used. The shape of the profile is asymmetrical, and the distribution of the reduction is uneven. The inner metal produces additional flow, which will increase rolling energy consumption and severe local wear of the pass shape. At present, the experience factor still plays an important role in the design of the pass system for production.

This production method needs to turn the rolling groove on the rolling wheel, and the rolling groove has a slope, the purpose is to make the rolled piece easy to enter the pass shape correctly, and it is also conducive to the rolling piece's de-grooving; moreover, the hole can be restored after rolling and regrinding. The original size of the rolling groove prolongs the service life of the rolling wheel. In addition, the side wall has a large slope and a large amount of lateral pressure, which is conducive to the extension of the rolled piece; the economic cross-section profiles, especially the groove depth are limited by the rolling strength, and the I-beams with wide flanges cannot be produced.

The pass of the universal rolling method is surrounded by three or more rolling passes, so it is also known as the multi-rod rolling method. This method is often used to produce H-shaped steel, parallel-leg channel steel, and rail.

The relative sliding between the rolled piece and the rolling wheel is small, avoiding steel surface cracking, and the steel surface quality is improved;

The universal pass method has a small speed difference, uniform wear on all parts of the pass, stable rolling dimensions, and a dimensional accuracy higher than that of the pass method by more than 30%.

Due to the uniform wear of the pass, the consumption of the rolling wheel is low. According to statistics, the consumption of rolling mix per ton of steel is reduced by about 2 kilograms compared to that of the pass method, and the commonality of the rolling wheel is increased;

Due to uniform metal deformation, the residual stress of the rolled piece is reduced, improving the mechanical properties of the rolled material;

It is possible to roll profiles with larger specifications using a smaller wheel diameter, especially to produce economic cross-section profiles that cannot be produced by the pass method, such as H-beams, thereby expanding the range of product varieties.

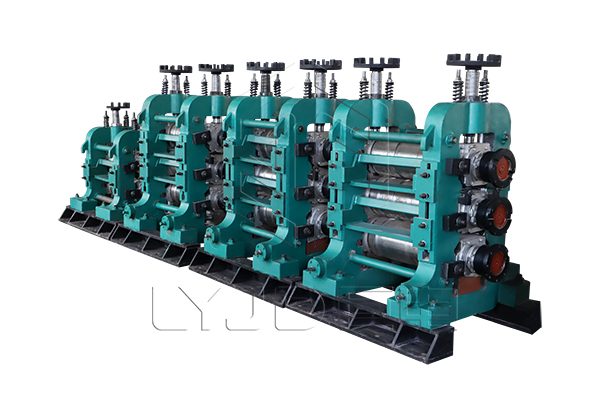

Luoyang Judian is a professional manufacturer of section steel rolling mills. Our yearly output of 20,000 tons section steel production line can produce high-quality section steel, such as flat and square steel.

If you have any problems with the section steel rolling mills, please leave us a message or consult online, and we will respond as soon as possible.

Please send us your request and we reply to you with in 24 hours.

Submit Request