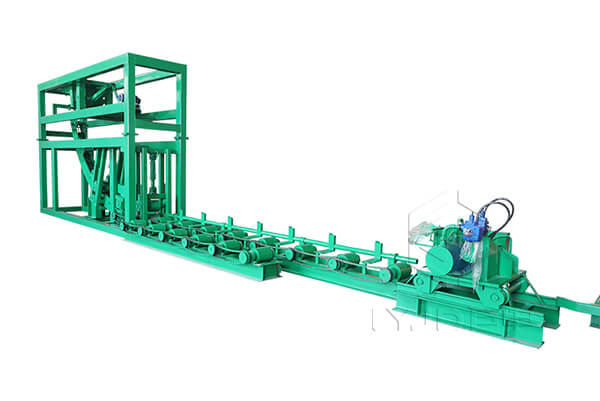

A continuous casting machine is a device used in the manufacturing process of metal casting. It is used to cast molten metal into a continuous semi-finished shape, such as a slab or a billet. The process involves pouring molten metal into a water-cooled mold, which allows the metal to solidify and form a continuous strand. The casting machine then extracts the strand and cuts it to the desired length. This process is used to produce a wide range of metal products, including steel, aluminum, and copper.

Continuous casting is a modern industrial technique that was first introduced in the 1950s. It has since become a widely used method for producing high-quality metal products with a consistent shape and size. The process involves several steps, including:

Melting the metal: The raw material is melted in a furnace, typically an electric arc furnace or an induction furnace;

Refining the metal: The molten metal is then refined to remove impurities and adjust its chemical composition to the desired level. This is done using various techniques, such as degassing, desulfurization, and deoxidation;

Casting the metal: The refined molten metal is then poured into a water-cooled mold, which is designed to produce the desired shape of the final product. As the metal cools, it solidifies into a continuous strand, which is gradually pulled out of the mold by a series of rollers;

Cutting the strand: Once the strand has reached the desired length, it is cut into individual pieces using a cutting machine.

Continuous casting has several advantages over traditional casting methods, including:

Higher efficiency: Continuous casting can produce metal products at a much faster rate than traditional casting methods, which can take several hours or even days to complete.

Improved product quality: Continuous casting produces metal products with a more uniform structure and composition, which results in higher quality and more consistent products.

Lower production costs: Continuous casting requires less labor and energy than traditional casting methods, which can result in lower production costs.

The continuous casting machine can vary in size and complexity, depending on the specific application. Some machines are designed to produce simple shapes, such as round bars or rectangular billets, while others can produce more complex shapes, such as steel beams or railway tracks. The process is highly automated, which allows for a high degree of precision and efficiency.

The continuous casting machine has revolutionized the metal casting industry, allowing for faster, more efficient, and higher-quality production of a wide range of metal products.

Please send us your request and we reply to you with in 24 hours.

Submit Request