A hot rolling mill is a facility that produces steel products by heating steel billets to high temperatures and passing them through a series of rollers to reduce their thickness and shape them into the desired final form.

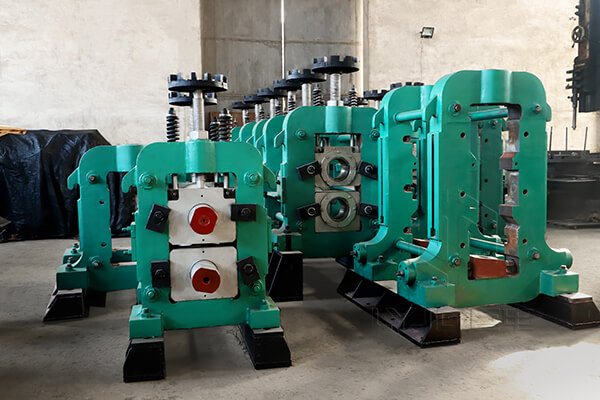

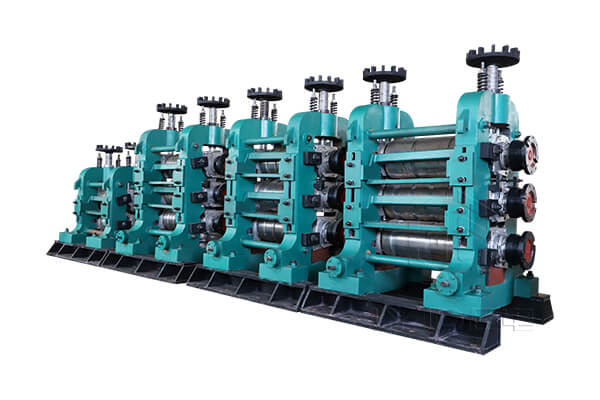

Hot rolling mills typically consist of a series of rolling stands, which are made up of two or more rollers that rotate in opposite directions. The rollers apply pressure to the steel as it passes through the mill, which causes it to deform and reduce in thickness and length. The rolling process can be used to produce a wide variety of steel products, including sheets, plates, bars, and rods, which are used in a range of applications such as construction, automotive, and aerospace.

Hot rolling mills can be divided into three main types: roughing mills, intermediate mills, and finishing mills. Roughing mills are used to reduce the thickness of the steel and shape it into a rough form, intermediate mills continue to roll the steel to further reduce the thickness, while finishing mills are used to further reduce the thickness and shape the steel into the final product.

The temperature for hot rolling steel typically ranges from 1100°C to 1250°C (2012°F to 2282°F), depending on the type of steel being rolled and the specific requirements of the rolling process. The steel must be heated to a temperature that is high enough to make it malleable and easy to deform, but not so high that it becomes too soft or loses its structural integrity.

The exact temperature used in the hot rolling process depends on several factors, including the type of steel being rolled, the thickness of the steel, and the desired final product. For example, higher temperatures may be used for thicker steel sections or for more complex products that require greater deformation. Conversely, lower temperatures may be used for thinner sections or for products with tighter dimensional tolerances.

The hot-rolling process typically involves the following steps:

The steel billets or slabs are heated to a temperature of around 1100-1250°C (2012-2282°F) in a furnace.

The heated steel is then passed through a series of rollers, which reduce the thickness of the steel and shape it into a rough form.

The steel is then passed through a series of finishing rollers, which smooth out the surface and further reduce the thickness of the steel to the desired final dimension.

After the rolling process is complete, the steel is cooled using water or air to prevent it from overheating and to improve its strength and durability.

Hot rolling mills are used to produce a wide range of steel products, including sheets, plates, bars, and rods. Here are three examples of products that are commonly produced on a hot rolling mill:

Hot rolling mills are used to produce large, flat sheets of steel that are used in a variety of applications, including construction, automotive, and packaging. The sheets can be produced in a range of thicknesses and widths, depending on the specific requirements of the application.

Hot rolling mills can also be used to produce long, thin bars of steel that are used in construction and engineering applications. The bars can be produced in a variety of shapes and sizes, including round, square, and hexagonal, and can be used for structural support, reinforcement, and other purposes.

Hot rolling mills can also be used to produce steel rails for use in the construction of railways and other transportation infrastructure. The rails are typically produced in long, straight sections that are designed to withstand the weight and stress of heavy trains and other vehicles.

There are several advantages of using a steel hot rolling mill.

The hot rolling process can improve the mechanical properties of steel, such as its strength, toughness, and ductility. This is because the process helps to refine the grain structure of the steel, which makes it more uniform and reduces the likelihood of defects.

Hot rolling mills are highly automated and use computer-controlled systems to monitor and control the rolling process. This can help to improve the efficiency of the process and reduce the amount of waste material produced. Additionally, continuous rolling in a tandem mill can result in higher production rates and reduced energy consumption.

Hot rolling mills can produce a wide range of steel products, including sheets, plates, bars, and rods, which can be used in a variety of applications. This versatility makes hot rolling mills an important part of the steel industry and allows them to meet the needs of a diverse range of customers.

Hot rolling mills can be cost-effective for producing large volumes of steel products. The use of continuous rolling and automated systems can help to reduce labor costs and increase production rates, which can help to lower the cost per unit of the final product.

The steel hot rolling mills provide an efficient and cost-effective way to produce high-quality steel products used in various industries and applications.

Please send us your request and we reply to you with in 24 hours.

Submit Request