A rebar production line is a manufacturing process used to produce reinforcing steel bars, also known as rebar.

The rebar production line typically includes several steps:

1. Scrap metal is first melted in a furnace;

2. The molten metal is then cast into billets;

3. The billets are then heated and passed through a rolling mill to reduce their size and shape them into a long, thin, and ribbed rod;

4. The rebar is then cooled down and cut into desired lengths;

5. The final step involves surface treatment and marking of the rebar for identification purposes.

The rebar production line is a highly automated process, which typically involves the use of computerized systems to control the various stages. This allows for consistent production and high-quality output, meeting the required standards for construction materials.

A rebar production line typically includes equipment that works together to produce reinforcing steel bars or rebar. The kit can vary depending on the production capacity and the particularities of the process. However, here is some of the standard equipment in a rebar production line:

Furnace

A furnace is to melt the scrap steel to create liquid metal used as raw material for the rebar. Two common furnaces used in rebar production are the electric arc furnace and the induction furnace.

This equipment is used to transform molten steel into semi-finished products called billets. The billets are then used as raw material for the following rolling process.

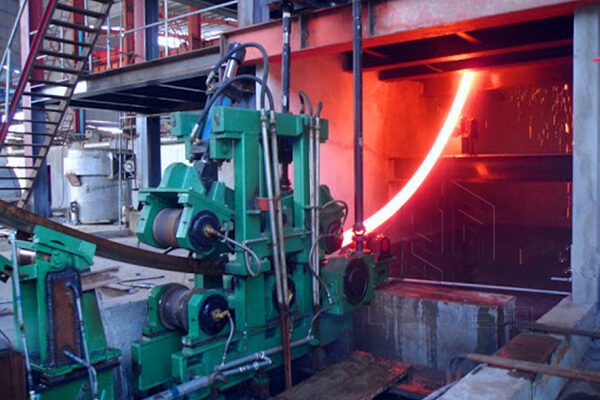

Rolling Mill

It is the most critical equipment in a rebar production line. The rolling mill is responsible for shaping the billets into rebar, by passing them between a series of rolls. The shape and size of the rolls can vary depending on the desired characteristics of the rebar.

Cooling Bed

After the rolling process, the freshly produced rebar needs to cool down. This equipment features a conveyor belt where the rebar is left to cool before being cut to the required lengths.

Cutting Machine

This equipment is responsible for cutting the rebar to the required lengths according to the customer's specifications. There are different types of cutting machines, including flying shears and cold shear machines.

Packing and Marking Lines

After the cutting process, the rebar will be packed in bundles and marked to indicate the length, grade, diameter, and other information.

High-end rebar production lines may include additional equipment such as preheating and descaling machines, heat treatment machines, and other quality control equipment.

There are several types of rolling mills used in the metalworking industry, and the type of rolling mill used depends on the type of metal being processed and the desired final shape and size. Some of the most common types of rolling mills include:

Two-High Rolling Mills

This is the simplest type of rolling mill, consisting of two large rolls that rotate in opposite directions. Two-high rolling mills are commonly used for flat products such as sheet metal and are typically used in a reversing process.

Three-High Rolling Mills

This type of rolling mill has three large rolls that rotate in the same direction and are stacked vertically. Three-high rolling mills can be used for both flat and profiled products.

Four-High Rolling Mills

This type of rolling mill has four rolls, two working, and two backup rolls. The rolls are arranged in a ‘2-2’ configuration and are used to improve the accuracy and flexibility of the rolling process. Four-high rolling mills are commonly used in the steel industry to produce strip steel.

Cluster Rolling Mills

This type of rolling mill consists of two or more sets of support rolls, with each set containing four or more rolls. Cluster rolling mills are used for high-speed rolling and are commonly used in the production of wire and rod.

Tandem Rolling Mills

In this type of rolling mill, multiple stands of rolls are set up in a line, allowing the metal to pass through each stand successively. Tandem rolling mills produce large quantities of continuous products, such as sheet metal or structural steel.

Each type of rolling mill has its own advantages and disadvantages, and the choice of rolling mill used will depend on the specific application, required tolerances, and the desired final properties of the metal product being produced.

Luoyang Judian is a professional manufacturer of the rebar production line and rolling mill. We can provide systematic solutions to the metal hot process. Welcome to inquiry.

Please send us your request and we reply to you with in 24 hours.

Submit Request