In the steel rolling production line, there will be some surface defects in hot rolled steel. The reasons for the defects are generally caused by the immaturity of the process. Today we will analyze the causes of the defects on the surface of the hot rolled steel and the solutions to these surface defects.

Common surface defects in hot rolled steel include cracks, folds, scars, scratches, etc.

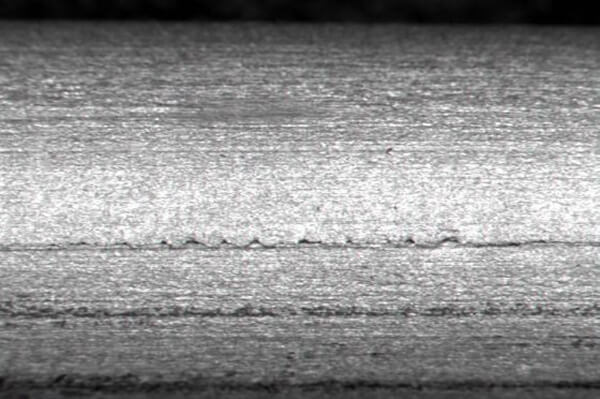

Crack

There are hair-like fine lines of different shades on the surface of the steel, which are generally unevenly arranged along the rolling direction.

Cause: There are bubbles inside the billet, and surface pores are generated during heating. The temperature during heating is uneven, and the billet temperature is low. The cooling of the billet is not handled properly.

Solutions: In steelmaking, degassing of molten steel should be done, the tapping temperature should be reduced, and protective pouring should be used to avoid secondary oxidation. Reasonable control of furnace temperature and cooling rate.

Folds

The surface of the steel is locally long or continuous, similar to cracks along the rolling direction. Generally it's linear.

Cause: The semi-finished coil has serious scratches and the coil is wrongly rolled. When the rolling stock is re-rolled, the corners cannot be elongated.

Solutions: Reasonably control the size of semi-finished products. During the production process, a wooden bar should be used to check whether there are lugs and staggered rolls on both sides of the roll gap; pay attention to the operating conditions of the rolled steel.

Scar

There are scars with irregular shapes and sizes on the surface of the steel.

Cause: The blank is defective, such as scarring, heavy skin, and inclusions. The semi-finished product is scratched by foreign objects.

Solutions: do not put unqualified billets into the furnace body; strengthen the quality inspection of rolls; reasonable channel design; often check the wear of the crossing, and reverse the crossing in time; the rolling stock transportation equipment and workplace should be clean and smooth.

Scratches

There are intermittent groove marks on the surface of the steel, and the shape is generally straight or arc.

Causes: The import and export guards for transporting steel are improperly installed, and the rolling stock transport equipment is scratched.

Preventive measures: Install guide devices for import and export, and use protective facilities correctly; rolling parts transportation equipment and workplaces should be clean and smooth.

That's what we share about the surface defects in hot rolled steel today. If you want to learn more about the hot rolling production line, please do not hesitate to get in touch with us.

Please send us your request and we reply to you with in 24 hours.

Submit Request